When it comes to Manufacturing or creating laser cutting designs and patterns, Laser cutting Machine and it’s various different types have been revolutionary. It has completely changed the way industries approach creative design and manufacturing their products. From Aeronautical Engineering to Locomotive Industry to Fabrication companies, everyone uses laser engraving and laser cutting today to achieve accuracy, efficiency and precision cutting.

A Laser cutting machine can offer versatility to your business if you’re thinking of buying one. But how do you determine the best laser cutting machine for your specific needs?

In this blog we will discuss about various types of laser cutting machine and its applications and which one is going to be a suitable purchase for your business.

Let’s dive in and discuss in elaborate detail what are the different types of laser cutting machines and what purpose they serve for different businesses.

The different types of Laser cutting machine available:

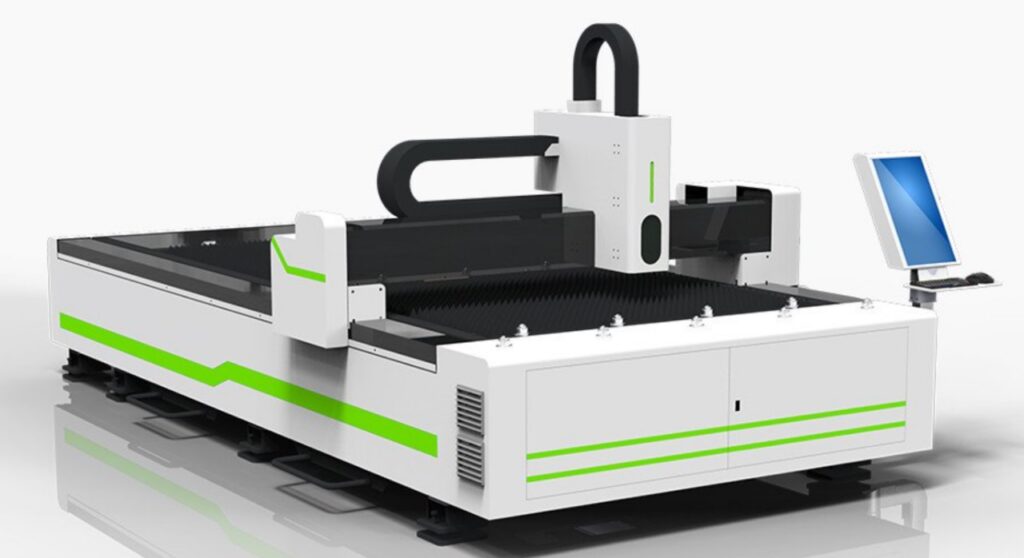

1) Fiber Laser Cutters

Fiber Laser cutters are one of the most commonly used machines that are very effective and powerful. Fiber based Laser cutting machines uses the heat of a fiber laser to melt and mold the workpiece material, causing a clean cut. It uses very narrow and precise laser beam to cut through the material with precision.

These machines are cost effective and have high precision in cutting and even provide high energy efficiency for those looking to invest in Fiber laser Machine. The initial investment cost of this machine is higher than most and requires a significant capital upfront.

2) CO2 Laser Cutters

CO2 laser cutters are machine that are used to cut a vast variety of materials including metal and Non-metal materials. These laser cutting machines produce laser beam in a sealed glass tube which is filled with a gas mixture with mostly Carbon dioxide in it. The laser beam is the redirected for precision cutting using strategically placed lenses and mirrors.

The CO2 laser cutters are powerful and versatile with a capability of cutting through many types of materials with a high production speed for thinner materials. Unlike the Fiber cutters, These machines do not leave residue or debris in the form of dust. If you are thinking of buying these keep in mind that CO2 laser cutters have a very high maintenance cost and require constant rechecking of mirrors and gas refills.

3) Direct Diode Lasers

The Direct Diode lasers are known for their exceptional efficiency, these Laser cutting machines use diode to produce lasers at a desired wavelength to give more precision and better designs. These laser cutters offer speed, electrical efficiency and compactness because of their smaller size. Quickly gaining popularity these lasers are preferred by small businesses and startups for their longevity and quick processing time.

Though restricted in terms of thickness of the material, these Machines can cut easily through a variety of metals and plastics materials. These laser cutters also have a lower beam quality in comparison to other machines. You should buy these machines if you are in an Industry where time is of the essence.

4) Nd:YAG/Nd:YVO Lasers

Nd:YAG (Neodymium doped Yttrium Aluminum Garnet) and Nd:YVO (Neodymium doped Yttrium Ortho Vanadate) lasers, also called the crystal laser cutters have a niche for many different Industries, because of their versatility and power. These Laser cutting machines are primarily used for laser engraving and marking.

Nd:YAG and Nd:YVO laser cutters are famous for their precisions and their ability to cut through materials and intricate designs that might be really hard for other laser cutters. These machines can cut through the hardest of materials and can create most complex of designs easily which is useful for industries where minute details are of paramount importance.

Conclusion

In Conclusion, Whether it is Fiber or CO2 laser cutters or Diode based or crystal based cutters, each one has it’s advantages and disadvantages and one should keep in mind their on requirements and needs when trying to buy one. Different laser cutting machines are suitable for different types of materials and industries, they serve specific purposes, for example if you want a compact laser cutter you should go for Direct diode lasers because of it’s compactness. Or if you want to cut through different types of fabric you should go for CO2 lasers which are already very popular in the Fashion Industry.

5 Things to consider when buying a Laser Cutting Machine:

1) Material Compatibility.

The first thing to consider when purchasing a Laser cutting machine is to check whether it is compatible with the material you want cut or engrave. If your business provides services for cutting and engraving wood material then the most suitable Laser cutting machine would be either Fiber cutters or CO2 cutters. It is wise to do comprehensive research about which machine goes best with the materials you want to cut.

2) Laser Power and Wattage.

The next most important thing to consider is to how much power and wattage does a Laser cutting machine requires. High wattage requirement would definitely lead to higher electricity consumption and in turn increase cost of manufacture, It is advisable to choose a machine that gives highest precision with lowest power requirement meanwhile also be within budget and expected cost per product.

3) Precision, Speed, and Accuracy.

How much precision does a laser cutting machine provide? does it lag when it comes to cutting complex designs? these are important questions to be asked when deciding on a laser cutter for yourself. Are you from a large industry which requires speed for better production or are you small business starting out of your garage which can do with slower speed but needs higher precision and accuracy. To answer these questions and doing detailed research can lead you to buy a good quality laser cutter machine.

4) Cutting Area and Machine Size.

The size of a laser cutting machine and the maximum area and dimensions it can cut through us very important when considering buying one. If you need a machine that is compact and can handle complex cuts then diode lasers might be best for you. but if your work requires you to cut large and thick materials with bigger dimensions and complicated designs then you might go for CO2 Lasers.

5) Software and Usability

The other notable thing when purchasing a laser cutting machine is how it operates meaning what kind of software and applications it requires or it’s compatible with. It is Important to use a laser cutter which is compatible with the popular Software such as CorelDraw, Adobe Illustrator or AutoCad.

Frequently Asked Question regarding Laser cutting machine:

Q1. Is it difficult to learn how to operate a laser cutting machine?

ANS1. No, it requires to learn how to use any required software and basic handling of the machines which can be learned under supervision of a more experienced laser cutting expert. It also depends on which kind of machine you are using and whether it is heavy duty and requires labour from multiple individuals.

Q2. Can I lease or rent a laser cutting machine?

ANS2. Yes, Laser cutting machines are available for lease and rent depending on your requirement. Many manufacturers and retailers of laser cutting machine provide the service of leasing and/or renting these machines on a charge of monthly payment.

Q3. Can a laser cutting machine be used for mass production?

ANS3. Yes heavy duty laser cutting are used in Large industries for mass production. Those machines are larger and requires better supervision and labour to operate on it. These machines are good for big companies with lots of different lines of products and goods to produce.

Q4. What software is compatible with laser cutting machines?

ANS4. There are many different software and applications available when it comes to operating on any laser cutting machine. The most commonly used software are Adobe Illustrator, CorelDraw and AutoCAD etc. Learning how to use these applications is very important when it comes to operating a laser cutting machine.

Q5. What safety certifications should I look for in a laser cutting machine?

ANS5. It is important to ensure that the machine you are buying meets latest safety requirements and follow safety regulations. Laser cutting machine must have certifications like CE, ISO 9001 etc. It must also contain safety measures like proper ventilation, emergency stop button, safety enclosures etc.

For the best Laser cutting service in West Delhi and nearby areas visit Hari Om Laser.